Controlled Environment for Precise ABS Results

The quality of ABS printing is significantly improved by using a 3D printer enclosure that ensures constant temperatures. This stability is crucial to prevent material warping, which is common with ABS without the approp

riate environmental conditions. A printer enclosure creates an insulated atmosphere that evenly distributes the necessary heat, optimizing print quality.

Protection from Environmental Factors and Temperature Fluctuations

A closed printer enclosure secures the printing area against external disturbances such as drafts and changing room temperatures. These elements are particularly critical for ABS material, as they can directly affect the quality of the final product. By controlling these factors, the printer enclosure enables more consistent and error-free prints.

Improvement of Mechanical Properties of ABS

In a stable printing environment, ABS cools more evenly, improving adhesion between layers and thus strengthening the mechanical properties of the printed objects. A printer enclosure ensures that ABS parts not only look higher in quality but are also structurally more stable.

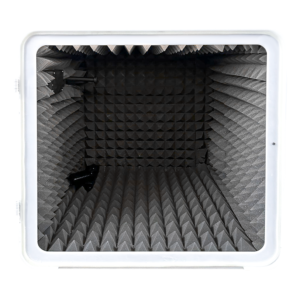

Increased Safety and Reduced Noise

The printer enclosure protects against potentially harmful ABS fumes and minimizes noise during the printing process. This reduction in noise pollution improves working conditions and enhances workplace safety.

Conclusion

A 3D printer enclosure is essential for anyone looking to achieve high-quality results with ABS material. It not only improves the quality and consistency of prints but also ensures a safer and more pleasant working environment. These advantages make the printer enclosure a worthwhile investment for both professional and hobby users of 3D printing technologies.

For more information on home printing improvements and other technical solutions, please visit our website.